This project we will be making a copystand bracket to

attach a 35mm size digital camera to a Polaroid MP4 Land Camera copystand.

My friend Doc Roach has made this wooden bracket, but it is too light

for his needs. The way Doc needs this made is for it to be out of metal,

preferably with an adjustible weight system to balance out his camera

with the springs in the head of the column so the camera will ride up

and down the stand with ease.

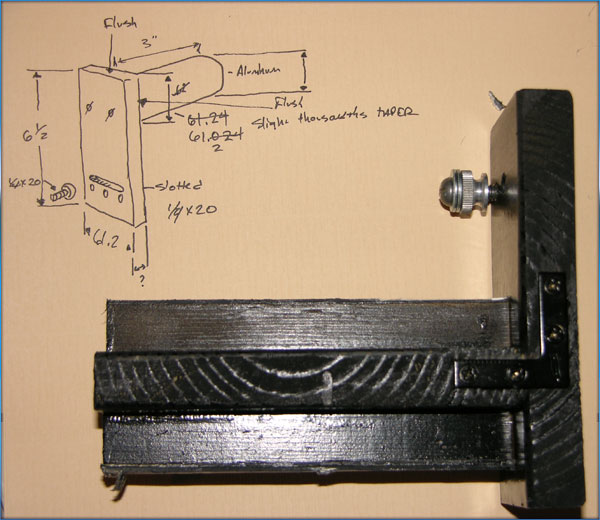

Here is the initial sketch of what I will machine out of aluminum next to the bracket Doc made.

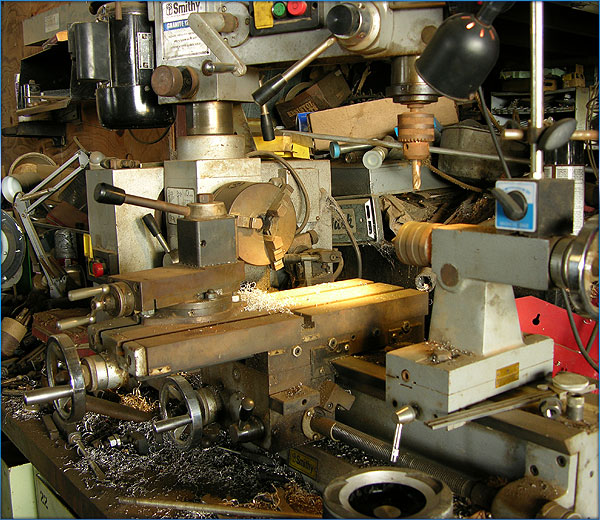

This is the Smithy Lathe and milling machine I'll be using for this and many other projects.

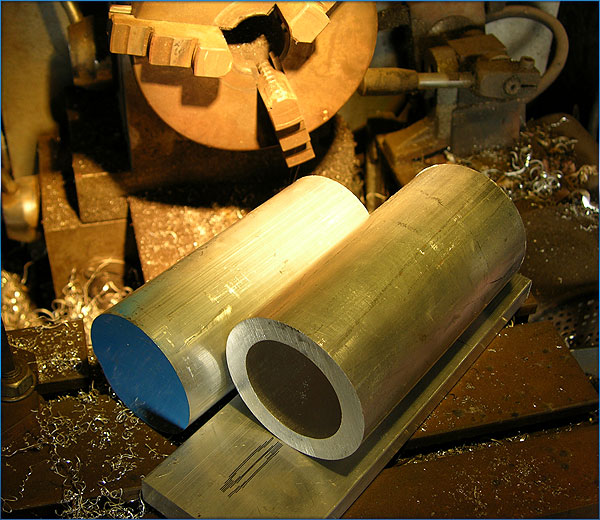

Here are our materials. I ordered these from AllMetals.com and they arrived the day before I was to head out to the ranch to begin work on this project.

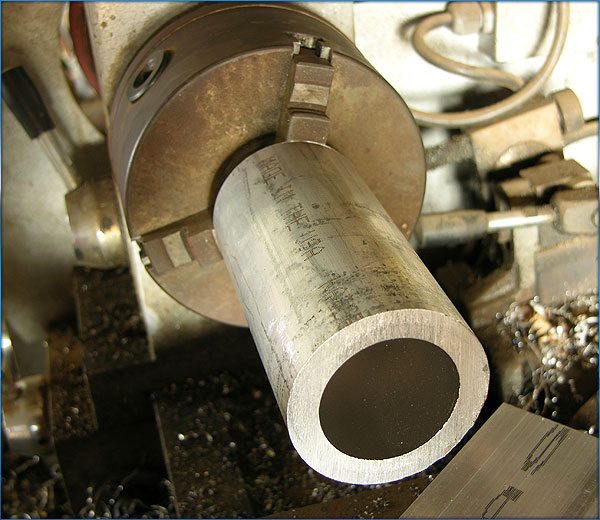

Here's the tube first chucked into the 3 way jaw.

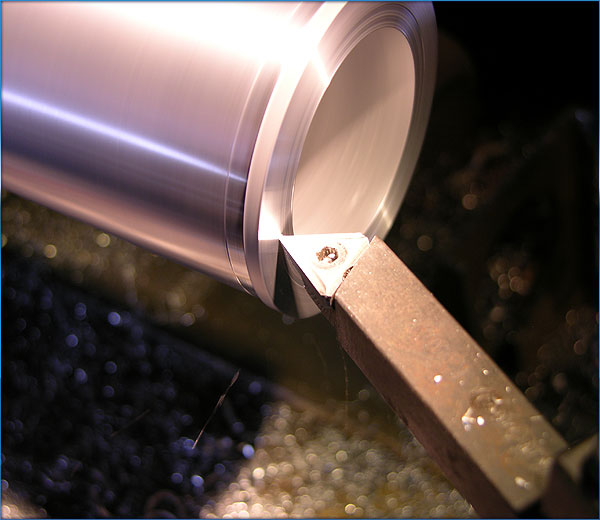

The first cut to reduce the outside diameter of the aluminum down to 62 mm.

The final few thousandths of an inch are removed slowly, as to help with the smooth finish.

The final diameter and cut of the aluminum tube.

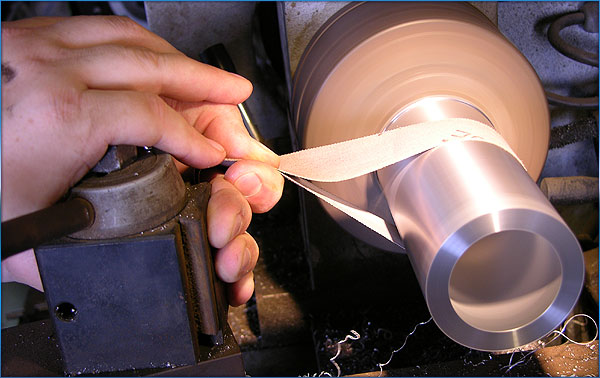

Next, I polish with emory tape. In order to get the finish even, I hold the tape tight against the stock, and rest against the tool post with the feed screw engaged. This lets me move the sanding tape evenly down the length of the stock.

Here we flip the tube around, rechuck it, and face off the unfinished end.

After the tube is cut to length, the threaded pipe end is welded into the tube using a heliarc aluminum welding machine.

Here the end cap is welded, and ready to be resurfaced.

Since we used aluminum rod to weld the aluminum end cap to the aluminum tube, once it's all cooled down, I can turn and face off the end seamlessly.

This is the Holdridge radii cutter I use to make radiused edges, balls, convex and concave curves in the aluminum.

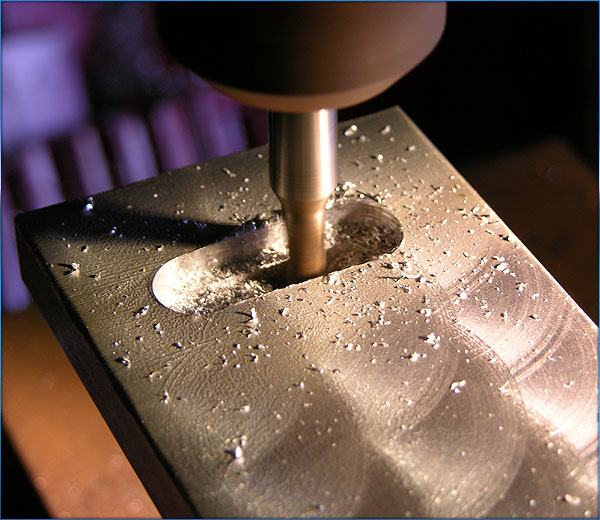

Once I am done with the tube, I need to mill out the slots for the camera mount screws. Notice the engine turned finish I applied to the plate with a rotary wire brush chucked into the overhead mill. Lowering the mill at every inch gives a nice engine turned aluminum finish akin to old airplanes, etc.

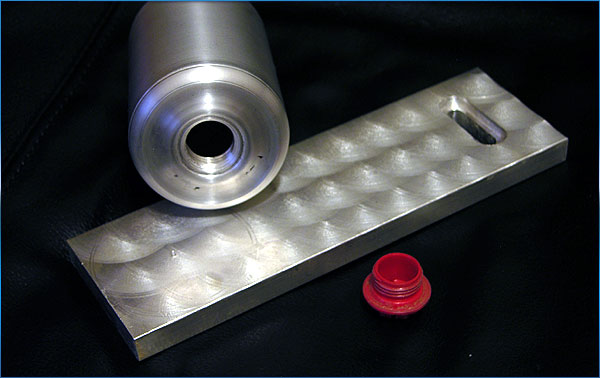

Here are the polished up pieces ready for drilling, tapping and assembly.

This is how the bracket will look once completed.

More to come as I get more time to work on this project.